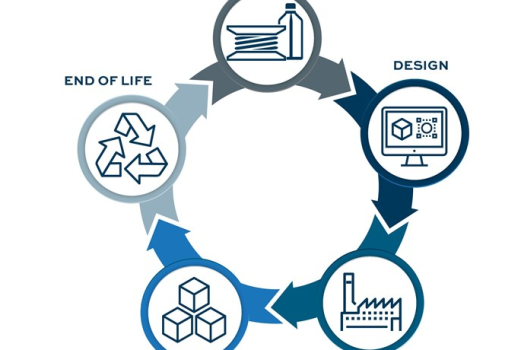

Circular economy principles are gaining momentum as more companies prioritize sustainable practices. Instead of traditional linear models where resources are extracted, manufactured into products, and ultimately disposed of, circular economy models prioritize resource recovery, waste reduction, and closed-loop systems.

In this article, we will explore how companies are implementing circular economy principles.

1. Design for Sustainability

Companies are adopting sustainable design principles to create products that are more environmentally friendly and durable. They are designing products with fewer components, reducing the use of non-renewable resources and using more sustainable materials such as bioplastics, recycled plastic, and natural fibers. The focus is on designing products that are easy to recycle or repurpose at the end of their life cycle.

2. Resource Recovery

Companies are finding ways to recover resources from waste streams and repurpose them into new products. They are using recycled materials in product manufacturing, repurposing waste materials into new products, and recycling end-of-life products into new materials. Resource recovery reduces the need for new raw materials and helps conserve natural resources.

3. Closed-Loop Systems

Companies are adopting closed-loop systems that keep resources in use for as long as possible. They are implementing product take-back programs, refurbishing and repairing products, and designing products for disassembly and reuse. Closed-loop systems aim to reduce waste and maximize the value of resources, extending their lifespan and reducing the environmental impact.

4. Collaborative Business Models

Companies are partnering with suppliers, customers, and other stakeholders to create more sustainable business models. They are collaborating on product design, sharing resources and knowledge, and developing circular supply chains. Collaborative business models enable companies to work together to reduce waste, improve efficiency, and promote sustainability.

5. Digitalization

Companies are using digital technology to optimize resource use, reduce waste, and improve supply chain transparency. They are using data analytics to identify waste reduction opportunities, using blockchain technology to track materials and products, and implementing smart logistics to optimize transportation and reduce emissions.

Digitalization enables companies to optimize their operations, reduce waste, and improve their environmental footprint.

6. Sustainable Packaging

Companies are implementing sustainable packaging solutions that reduce waste and improve recyclability. They are using compostable and biodegradable packaging materials, reducing packaging waste through design optimization, and developing packaging take-back programs. Sustainable packaging reduces the environmental impact of packaging waste and helps conserve natural resources.

7. Energy and Water Efficiency

Companies are prioritizing energy and water efficiency in their operations to reduce their environmental impact. They are implementing renewable energy sources, optimizing production processes to reduce energy and water consumption, and investing in water treatment and recycling technologies.

Energy and water efficiency measures reduce greenhouse gas emissions, conserve natural resources, and promote sustainability.

Implementing circular economy principles requires a significant shift in business practices and mindset, but the benefits are significant. Companies that prioritize sustainability and circularity can reduce costs, improve resource efficiency, and build more resilient and sustainable supply chains.

By embracing circular economy principles, companies can not only reduce their environmental impact but also drive innovation and growth in a rapidly changing world.